Gas Drying ( natural gas, methane, and other hydrocarbon streams )

Removal of CO2 and H2S (carbon dioxide – CO2 and hydrogen sulfide – H2S )

Air Purification (carbon dioxide and moisture, resulting in cleaner and dryer air )

Petrochemical Industry ( purification of various feedstocks and products )

Ethanol Dehydration

Hydrogen Purification

Air Separation ( while production of high-purity oxygen or nitrogen )

Refrigerant Drying

Medical Oxygen Production

Precise pore size: Its defining characteristic is a pore size of 5 angstroms (Å), allowing it to selectively adsorb molecules with similar or slightly larger sizes while excluding smaller ones.

High adsorption capacity: Due to its large internal surface area, 5A molecular sieve can adsorb a significant amount of molecules onto its pore walls. This capacity makes it efficient and cost-effective for various industrial applications.

Strong adsorption affinity: It exhibits strong binding with specific molecules, particularly water molecules and polar gases like carbon dioxide.

Chemical stability: 5A molecular sieve is resistant to heat, acids, and alkalis, making it durable and suitable for harsh operating conditions in many industrial processes.

Regenerability: After adsorbing its target molecules, it can be regenerated by heating or purging with an inert gas, allowing for repeated use over an extended period.

- Fibre Drum and M.S.drum ( customization available ).

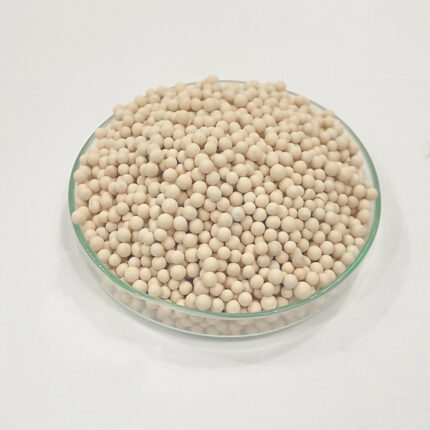

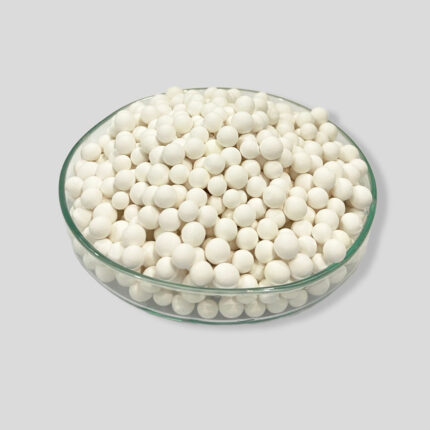

- Molecular Sieves 5A available in the form of beads / pellets / powder.