Dehydration of Liquids: ( ethanol, methanol, and natural gas liquids )

Removal of Water from Gases: ( Air, Industrial Gases )

Protection of Sensitive Equipment ( electronic devices, optical instruments, sensitive analytical instruments. )

Refrigerant Drying:

Air Purification:

Natural Gas Processing:

Insulating Glass Manufacturing

Desiccant for food, electronics, and other products

Petroleum refining

Olefin Drying

Drying Cracking Liquid and Cracking Gas

1. Highly Selective Adsorption: This makes them ideal for drying applications, as water molecules (2.6 Å) are readily adsorbed while larger molecules like hydrocarbons (ethane: 4.8 Å).

2. High Adsorption Capacity: 3A sieves can adsorb a large amount of water vapor onto their internal surface area. This means they can effectively remove moisture from a variety of liquids and gases.

3. Fast Adsorption Kinetics: 3A sieves have a high diffusion rate for molecules within their pores. This allows them to quickly adsorb water vapor, making them suitable for applications where rapid drying is required.

4. Regeneration: 3A sieves can be regenerated by heating them to drive off the adsorbed water molecules. This allows them to be reused multiple times, making them an economical and sustainable solution.

5. Chemical Stability: 3A sieves are resistant to most chemicals and solvents. This makes them suitable for a wide range of industrial applications.

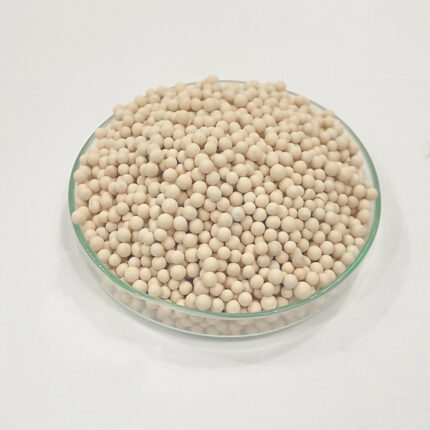

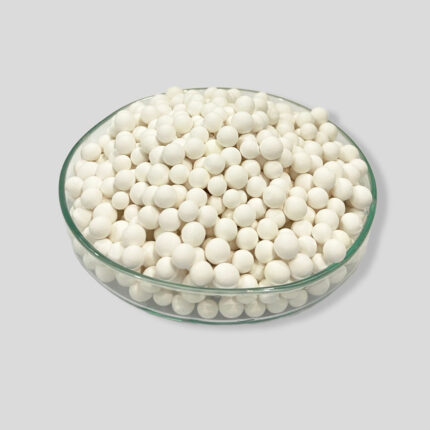

6. Mechanical Strength: 3A sieves are available in various forms, including beads and pellets, which have good mechanical strength and abrasion resistance. This makes them suitable for use in packed beds and filters.

Fibre Drum and M.S.drum ( customization available ).

Molecular Sieves 3A available in the form of beads / pellets / powder.