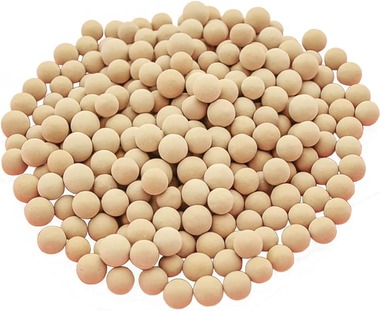

Molecular sieves are crystalline materials with uniform pores that allow them to selectively adsorb molecules based on their size and shape. These materials have various applications across different industries, and their benefits include:

Adsorption and Dehydration: One of the primary uses of molecular sieves is to adsorb and remove water molecules from liquids and gases. This dehydration capability is particularly important in industries such as natural gas processing, petrochemical, and pharmaceutical manufacturing.

Selective Adsorption: Molecular sieves can selectively adsorb specific molecules while excluding others based on their size and shape. This property is valuable in processes like separating isomers or purifying gases and liquids.

Improved Product Quality: By removing impurities and unwanted molecules, molecular sieves contribute to the improvement of product quality. This is especially crucial in industries like the production of high-purity chemicals and pharmaceuticals.

Gas Separation: Molecular sieves are used in gas separation processes, such as the removal of carbon dioxide, nitrogen, and water vapor from air. This is essential in applications like air separation for the production of nitrogen and oxygen.

Hydrocarbon Drying: Molecular sieves are effective in drying hydrocarbon streams, ensuring the removal of moisture from gases and liquids. This is important in processes such as natural gas processing and refining.

Catalyst Support: Molecular sieves can serve as catalyst supports in various chemical reactions. They provide a stable framework for catalysts and can enhance the overall efficiency of the catalytic process.

Drug Formulation: In the pharmaceutical industry, molecular sieves are used in drug formulation to control the release of active pharmaceutical ingredients (APIs). They can act as carriers for drug delivery systems, providing controlled and sustained release.

Insulating Glass: Molecular sieves are utilized in insulating glass units to adsorb moisture, preventing condensation between the glass layers. This helps maintain the insulating properties of the glass.

Refrigerant Drying: Molecular sieves are employed in the drying of refrigerants, ensuring the removal of moisture, which can otherwise lead to corrosion and reduced efficiency in refrigeration systems.

Environmental Applications: Molecular sieves are used in environmental applications, such as air purification and water treatment, to remove pollutants and contaminants.

In summary, the benefits of molecular sieves span various industries, contributing to improved processes, product quality, and efficiency in applications ranging from gas separation to pharmaceuticals and beyond.