- Gas Drying ( natural gas and air )

- Air Purification

- Pet Drying

- Dehydration of Solvents

- Refrigerant Drying

- Petroleum Refining

- Ethanol Dehydration

- Drying and Purification of Liquids

- Selective Adsorption

- Pre Purification Unit before Cryogenic plant

- Removal of Mercaptan from LPG Gas

- Carbon dioxide enrichment in Beverages

High surface area and porosity: 13X molecular sieves are made from a synthetic zeolite called sodium aluminosilicate.

Selective adsorption: The pores of 13X molecular sieves are only large enough to allow smaller molecules, such as water, carbon dioxide, and nitrogen, to enter.

High adsorption capacity: 13X molecular sieves can adsorb a large amount of gas or liquid molecules onto their surface before they become saturated. This high adsorption capacity makes them ideal for use in a variety of industrial applications, such as gas drying, air purification, and petroleum refining.

Regeneration: Once 13X molecular sieves have become saturated with adsorbed molecules, they can be regenerated by heating them to a high temperature. This drives off the adsorbed molecules and allows the sieves to be reused.

Chemical stability: 13X molecular sieves are resistant to most chemicals and can be used in a wide range of operating conditions.

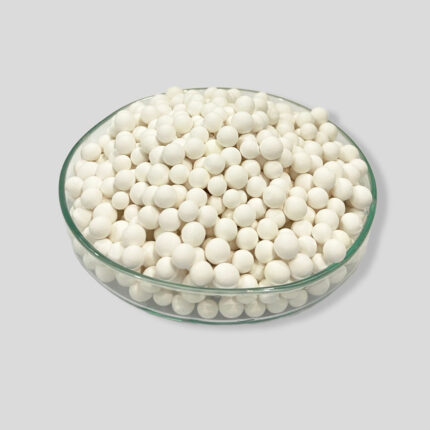

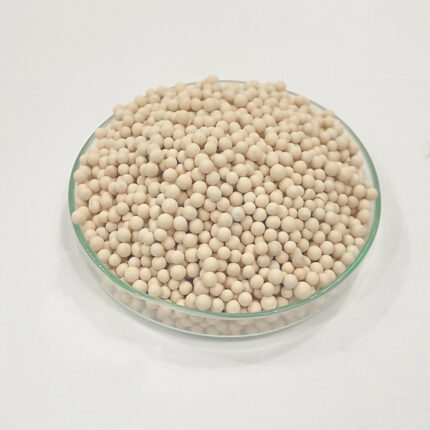

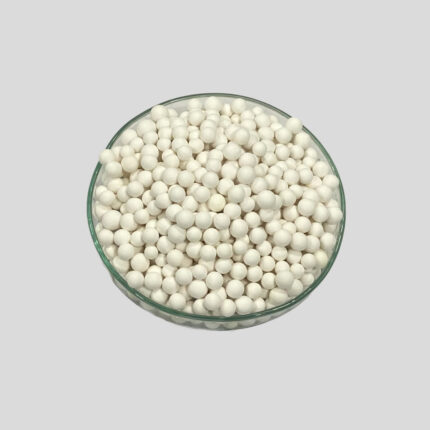

Mechanical strength: 13X molecular sieves are available in a variety of shapes and sizes, including beads, pellets, and powders. They are also relatively strong and durable, making them suitable for use in industrial applications.

- Fibre Drum and M.S.drum ( customization available ).

- Molecular Sieves 13X available in the form of beads / pellets / powder.