Dehydration of gases ( natural gas, carbon dioxide, and air )

Refrigerant drying

Drying of liquids ( solvents and petrochemicals etc )

Insulating glass manufacturing

Air compression systems

Petroleum refining ( to remove water and impurities from hydrocarbons )

Drying of alcohols and solvents

Cosmetics and pharmaceuticals manufacturing

Natural gas drying for fuel cells

Coatings, Sealants & adhesive

Protection for metallic paints

High adsorption capacity: 4A sieves have a large internal surface area and a uniform pore size of about 4 angstroms (Å), which allows them to adsorb a large amount of water and other small molecules. This makes them highly effective as desiccants and for separating gas mixtures.

Selective adsorption: The small pore size of 4A sieves allows them to selectively adsorb molecules that are smaller than 4 Å in diameter.

Thermal stability: 4A sieves are stable at high temperatures, up to 800°C. This makes them suitable for use in high-temperature applications such as the regeneration of other adsorbents and the removal of water from hot gases.

Chemical stability: 4A sieves are resistant to most chemicals, including acids, bases, and organic solvents. This makes them suitable for use in a wide range of industrial applications.

Regeneration: 4A sieves can be regenerated by heating them to remove the adsorbed molecules. This allows them to be reused multiple times.

Cobalt chloride indicator:

Fibre Drum and M.S.drum ( customization available ).

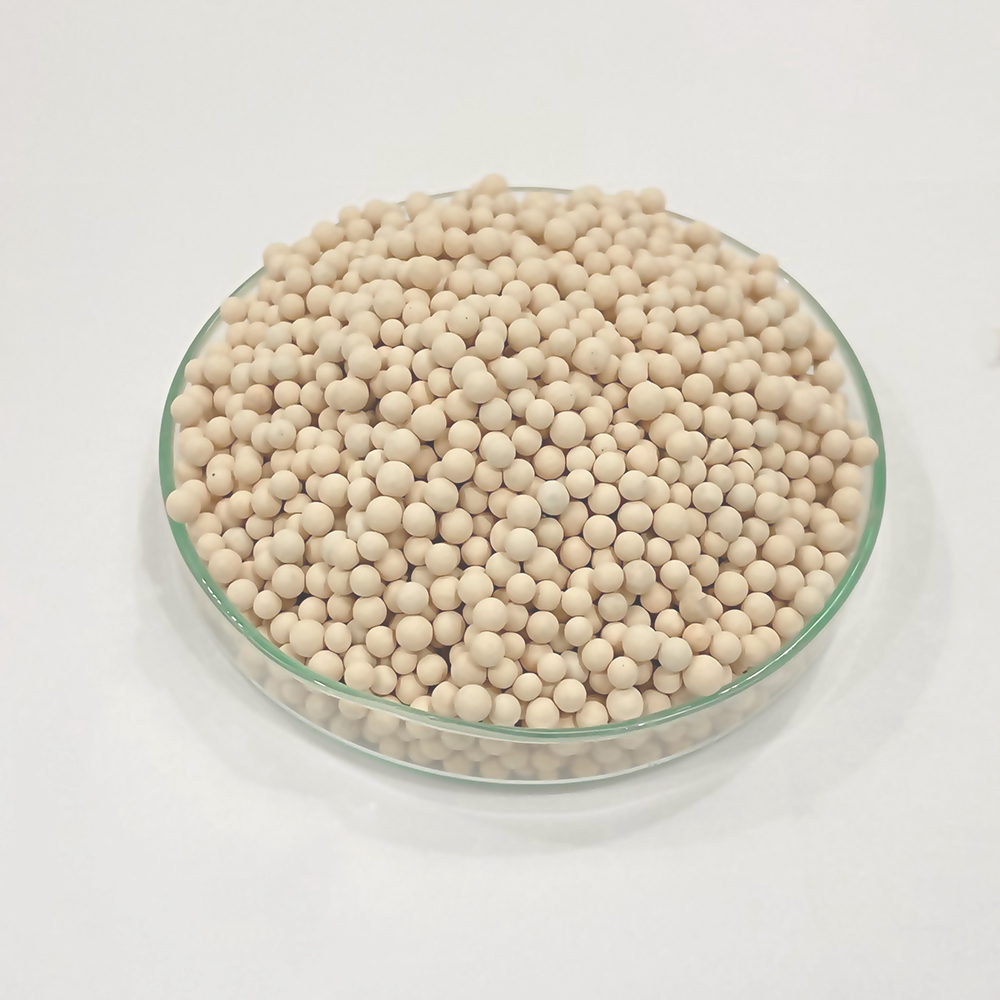

Molecular Sieves 4A available in the form of beads / pellets / powder.